Ngesantya sophuhliso lwesayensi kunye nethekhnoloji, iimveliso ezininzi zokubonisa ngoku zixhotyiswe ngezikrini zokuchukumisa. Ukuxhathisa kunyecapacitive touch screenssele zikho kuyo yonke indawo ebomini bethu, ke ngaba abavelisi besiphelo kufuneka benze ngokwezifiso ulwakhiwo kunye ne-LOGO xa uxhasa uchuku? Zeziphi iinkcukacha ekufuneka ziqwalaselwe xa usenza ngokwezifiso?

Apha siqala ukusuka kwiinkcukacha ze-6 ukwazisa ukuchasana kunyeisikrini sokuchukumisa amandlaiskimu sokwenza ngokweenkcukacha:

1. Iiparamitha zokuchukumisa

Okokuqala, kufuneka uqinisekise ukuba imveliso ifanelekile kwi-capacitive okanye i-resissive touch screens, kwaye uqinisekise ukushisa okusebenzayo, ukushisa kokugcina, ujongano kunye nezinye iimfuno zeparameter. Kungcono ukugxila ekuxoxeni nasekuhleleni itafile yeemfuno zeparameter, enokunciphisa kakhulu ixesha lonxibelelwano lokuqala.

2. Ubungakanani be-AA kunye nobukhulu besakhelo sangaphandle

Emva kokuqinisekisa iiparamitha ezifunekayo, ngokulandelayo qinisekisa ubungakanani bemveliso. Ubungakanani ubukhulu becala yindawo ye-AA yesikrini sokuchukumisa kunye nobukhulu besakhelo sangaphandle. Ezi zikhulu zimbini ngokuqhelekileyo ziyilwe ngokusekelwe kwisakhiwo. Injineli yesakhiwo izoba imizobo ye-CAD yokuqinisekisa, enokuphucula ukusebenza kakuhle.

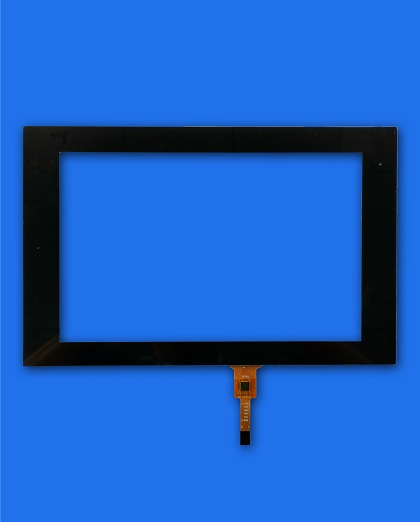

3. Ilogo yekhava yokuchukumisa

Kwizikrini ezigcweleyo ezigcwele i-capacitive touch screen, isigqubuthelo sesikrini sokucofa sinokwenziwa ngokwezifiso. I-SIlk-printed LOGO okanye imifanekiso inokwenziwa ngokwezifiso kwisikrini sokuchukumisa. Ukuba abathengi bafuna ukwenza i-inshorensi ngokwezifiso, banokunxibelelana nomenzi kwangexesha.

4. Isakhiwo sesikrini sokuchukumisa

Kukho iintlobo ezininzi zezikrini zokuchukumisa, kuquka i-G + G, G + F + F, G + F, G + P, njl. Nceda uqinisekise isakhiwo sokuchukumisa. Isakhiwo ngasinye sineempawu zaso. Ungaqhagamshelana nenkonzo yabathengi ukubonelela ngeenzuzo ezahlukeneyo kunye nokungalunganga kwesi sakhiwo.

5. Isikrini sokucofa silingana

Kukho ngokubanzi iindidi ezimbini zeendlela zokucofa i-lamination: i-optical bonding kunye ne-air bonding. I-Optical bonding isebenzisa umatshini ozenzekelayo we-glue lamination yamanzi. Izibonelelo zayo zingcono ukubonisa umphumo kunye nokuxhathisa uthuli, ngelixa ukudibanisa umoya kunamandla. Nganye ineengenelo zayo, kwaye amashishini ahlukeneyo asebenzisa iindlela ezahlukeneyo zokuthambisa.

6. Touch screen IC debugging

Iisampuli zesikrini sokuchukumisa ziya kulungiswa emva kokushiya umzi-mveliso. Iinkqubo zokucwangcisa ziya kwahluka kwii-ICs ezahlukeneyo. Ezinye iibhodi ezingundoqo azihambelani kakuhle, ngoko ke ukulungisa iimpazamo kunye nokutshintsha inkqubo kuyafuneka ukuze kuphunyezwe imisebenzi yochuku.

Okokugqibela, makhe sishwankathele umba wexesha lokuhanjiswa kwesikrini esichukumisayo. Ixesha lokuhambisa libaluleke ngakumbi kumthengi. Ngokubanzi, ukuba ulungelelanisa kuphela iglasi yokugubungela, ixesha lokuhambisa lihlala liphakathi kweeveki ezi-1 kunye neeveki ezi-2. Ukuba isikrini sokuchukumisa silungiselelwe ngokubanzi, ixesha lokuhambisa li malunga neentsuku ze-20, kuxhomekeke kwimeko yezinto zokuqala. Ukuba izinto eziphathekayo aziphelelanga, umhla wokuhanjiswa uya kuqinisekiswa ngokwahlukileyo.

DISEN ELECTRONICS CO., LTDigxile ekwenzeni izikrini zeLCD, iTP, kwaye inokwenza iimveliso ngokweemfuno zabasebenzisi. Ukuba unayo nayiphi na imibuzo, nceda uzive ukhululekile ukudibana nenkonzo yabathengi kwi-intanethi.

Ixesha lokuposa: Feb-29-2024